Braycote 631 RP

Grease, Rust Preventive, Rocket Propellant Compatible Low TemperatureBraycote 631 RP is available in 2 oz syringe, 1 lb can, 1.75 lb cartridges.

Braycote 631 RP Description

Castrol Braycote 631RP is a smooth, buttery, off-white NLGI #2 grease based upon a perfluoroether oil. Braycote 631RP is nonflammable and is in general chemically inert.

Braycote 631RP is thermally stable either alone or in the presence of oxygen, has exceptionally low volatility, and has little tendency to form deposits.

In addition Braycote 631RP exhibits excellent lubricating properties, good dielectric properties, and shear stability. Castrol Fluoroclean™ X100 and Castrol Fluoroclean™ HE can be used to remove this lubricant. Refer to the data sheets for information regarding these products.

Braycote 631 RP Uses

Braycote 631RP is designed for static or dynamic service in the presence of fuels and oxidizers. Braycote 631RP has been used in gears, ball and roller bearings, electrical contacts, and as a thread and elastomer sealant.

Braycote 631 RP is particularly useful as a lubricant in corrosive or oxygen (LOX/GOX) service and as a plug valve lubricant.

Braycote 631RP is compatible with concentrated acids and bases and it does not hydrolyze or oxidize. Perfluorinated greases, such as Braycote 631RP, exhibit excellent shelf lives due to their inertness.

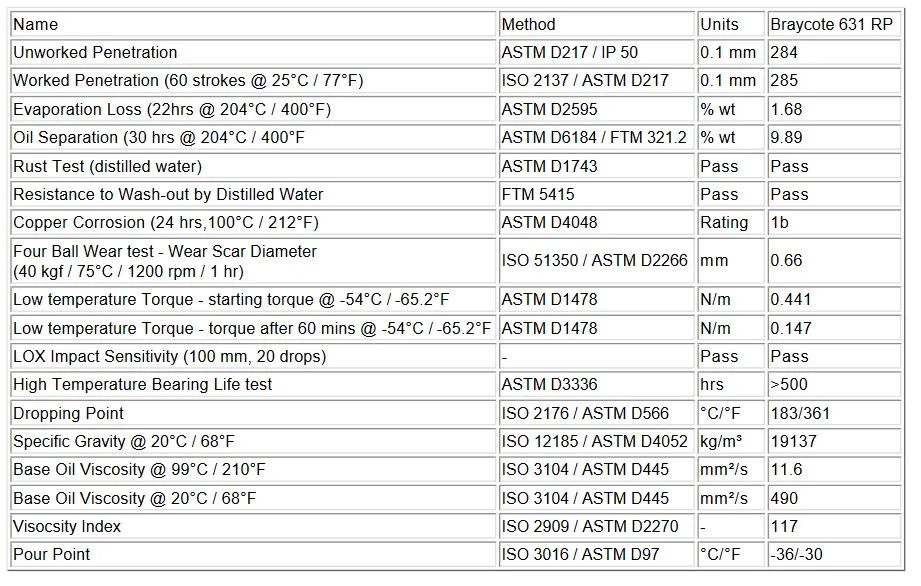

Braycote 631 RP Typical Properties

Braycote 610 Temperature Range

Temperature Range: -54ºC to above 204ºC (-65ºF to above 400ºF)

Braycote 610 Limitations

Braycote 631RP is only slightly soluble or insoluble in most current fuels and oxidizers in propellent service, and in most organic solvents and materials other than fluorinated solvents.

Braycote 631RP is compatible at normal operating temperatures with conventional metals, plastics and elastomers.

Braycote 631 RP may be adversely affected by Lewis Acids, such as aluminum chloride, at elevated temperatures. Newly exposed rubbing surfaces of aluminum, magnesium or titanium alloys may react with Braycote 631RP under certain conditions. Such systems should be thoroughly evaluated. Surfaces must be well cleaned of organic rust inhibitors prior to grease application to insure proper lubrication.