CHEVRON SRI GREASE 2

High Temperature Ball And Roller Bearing Grease

CHEVRON SRI GREASE 2 CUSTOMER BENEFITS

Chevron SRI Grease 2 delivers value through:

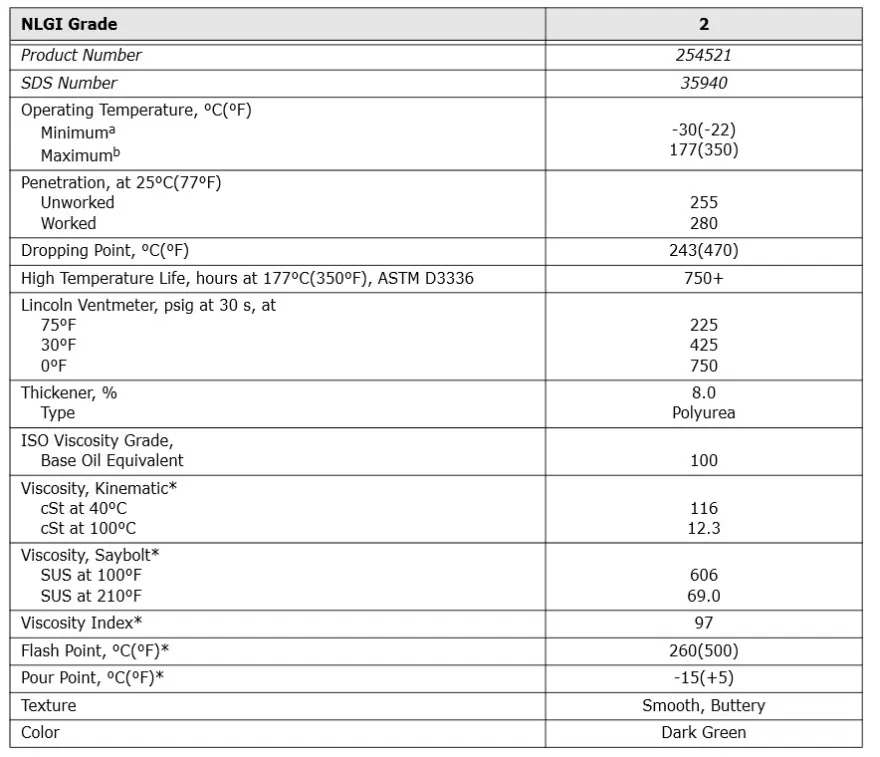

•Wide application range — Suitable for high rpm operation, operating temperatures ranging from -30°C to 177°C (-22°F to 350°F).

•Excellent oxidation stability — Provides exceptional bearing life at operating temperatures in the range of 93°C to 177°C (199°F to 350°F).

•Excellent rust protection — Provides rust protection as defined by ASTM D5969 with 10% Synthetic Sea Water.

CHEVRON SRI GREASE 2 FEATURES

Chevron SRI Grease 2 is a high temperature ball and

roller bearing grease.

It is formulated with highly refined base stocks, a modern ashless, organic polyurea thickener coupled with high performance rust and oxidation inhibitors (the latter to provide outstanding rust protection in severe applications that many electric motor applications are exposed to in field operations).

Its texture is smooth and buttery and its color is dark green.

As noted, Chevron SRI Grease 2 passes the Static Bearing Rust Test, ASTM D5969, with 10% synthetic sea water. These properties help to provide longer bearing life under high speed and high temperature operation. This is nearly 10 times the life possible when using conventional lithium greases. Under normal operating temperatures and conditions, Chevron SRI Grease 2 can be used as a “Life Pack" lubricant in

sealed bearings

Note that in today’s more modern, high output (horsepower), high load electric motors, there are times where these units employ ball bearings and roller element bearings on the same motor. On units where horsepower and load are considered high on the roller element bearing, EP greases should be employed. In these instances, Black Pearl® Grease EP would be the grease of choice and is fully compatible to use with

Chevron SRI Grease 2.

CHEVRON SRI GREASE 2 APPLICATIONS

• Chevron SRI Grease 2 is recommended:

• for use in a wide range of automotive and industrial applications

• for use in antifriction bearings operating at high speeds (10,000 rpm and greater)

• where the operating temperatures are on the order of 150°C (302°F) and higher

• where there is a likelihood that water or salt water will get into the bearings

Chevron SRI Grease 2 will perform in bearings at temperatures as low as -30°C (-22°F).

Chevron SRI Grease 2 is registered by NSF and is acceptable as a lubricant where there is no possibility of food contact (H2) in and around food processing areas.

The NSF Nonfood Compounds Registration Program is a continuation of the USDA product approval and listing program, which is based on meeting regulatory requirements of appropriate use, ingredient review and labeling verification

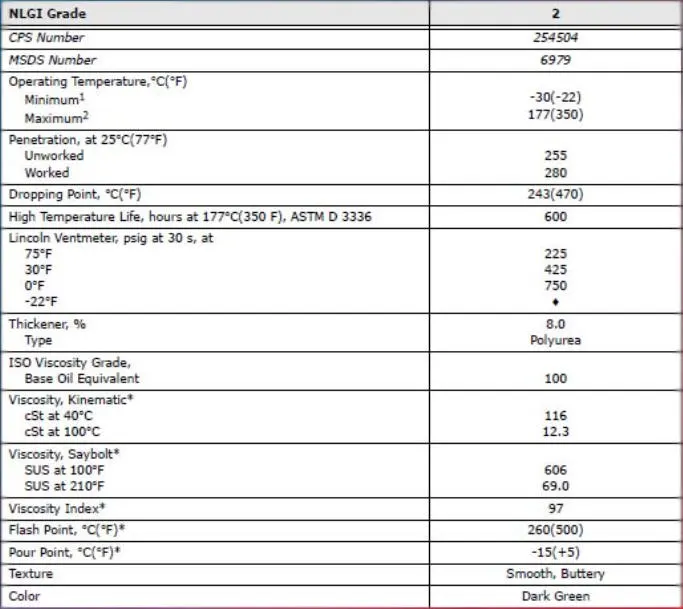

Typical test data are average values only. Minor variations which do not affect product performance are to be expected in normal manufacturing. 1 Minimum operating temperature is the lowest temperature at which a grease, already in place, could be expected to provide lubrication. Most greases cannot be pumped at these minimum temperatures. 2 Maximum operating temperature is the highest temperature at which the grease could be used with frequent (daily) relubrication. * Determined on mineral oil extracted by vacuum filtration. ♦ Not tested at this temperature. † Too stiff at this temperature to pump through device. Minor variations in product typical test data are to be expected in normal manufacturing.