CHEVRON MULTIFAK® EP

Formerly DURA-LITH® GREASES EP NLGI 000, 00, 0, 1, 2

CHEVRON MULTIFAK® EP CUSTOMER BENEFITS

CHEVRON MULTIFAK® EP deliver value through:

CHEVRON MULTIFAK® EP deliver value through:

• High film strength — Timken Film Test Rating 40 pounds and above indicates high load-carrying capacity and low wear rate.

• Good water resistance — Provide lubrication in the presence of water.

• Good corrosion protection — Inhibited to protect bearing surfaces.

• Good oxidation stability — Helps to ensure long life in storage and in use.

• Simplified lubrication — One grease designed to satisfy most industrial grease requirements.

• Economy — Reduced inventory since these greases can replace many specialized products. Reduce chance of applying the wrong lubricant.

• Low oil bleeding tendency — Recommended for use in centralized lubrication systems.

CHEVRON MULTIFAK® EP FEATURES

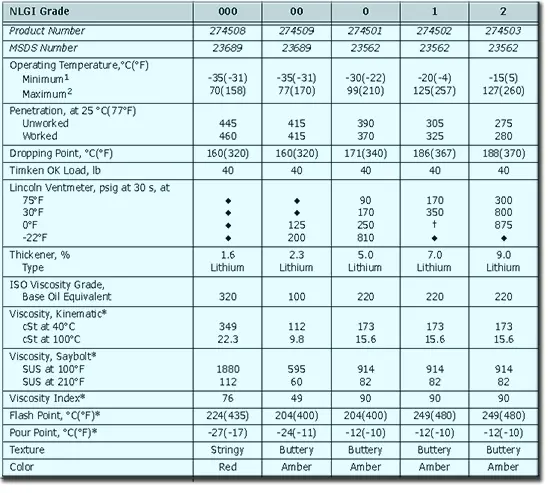

Chevron Dura-Lith Greases EP are multipurpose extreme pressure greases. They are manufactured using selected highly refined medium viscosity index base oils, a lithium 12- hydroxystearate thickener, an extreme pressure additive, and rust and oxidation inhibitors. NLGI 000 is red in color and stringy in texture. NLGI 00, 00, 0, 1 and 2 are amber in color and buttery in texture. Chevron Dura-Lith Greases EP have high load-carrying capacity and, therefore, provide good protection of lubricated parts against wear. They provide excellent lubrication in the presence of water, protect bearing surfaces against corrosion, and have excellent resistance to oxidation, which ensures long life in storage and in use. They are work stable. They resist separation or throw out from antifriction bearings. They have low oil bleeding tendency under pressure and are pumpable at low temperatures.

CHEVRON MULTIFAK® EP APPLICATIONS

CHEVRON MULTIFAK® EP deliver value through:

• High film strength — Timken Film Test Rating 40 pounds and above indicates high load-carrying capacity and low wear rate.

• Good water resistance — Provide lubrication in the presence of water.

• Good corrosion protection — Inhibited to protect bearing surfaces.

• Good oxidation stability — Helps to ensure long life in storage and in use.

• Simplified lubrication — One grease designed to satisfy most industrial grease requirements.

• Economy — Reduced inventory since these greases can replace many specialized products. Reduce chance of applying the wrong lubricant.

• Low oil bleeding tendency — Recommended for use in centralized lubrication systems.

Typical test data are average values only. Minor variations which do not affect product performance are to be expected in normal manufacturing. 1 Minimum operating temperature is the lowest temperature at which a grease, already in place, could be expected to provide lubrication. Most greases cannot be pumped at these minimum temperatures. 2 Maximum operating temperature is the highest temperature at which the grease could be used with frequent (daily) relubrication. * Determined on mineral oil extracted by vacuum filtration. ♦ Not tested at this temperature. † Too stiff at this temperature to pump through device. Minor variations in product typical test data are to be expected in normal manufacturing.