TECTYL® 502C

SOLVENT CUTBACK CORROSION PREVENTIVE COMPOUND

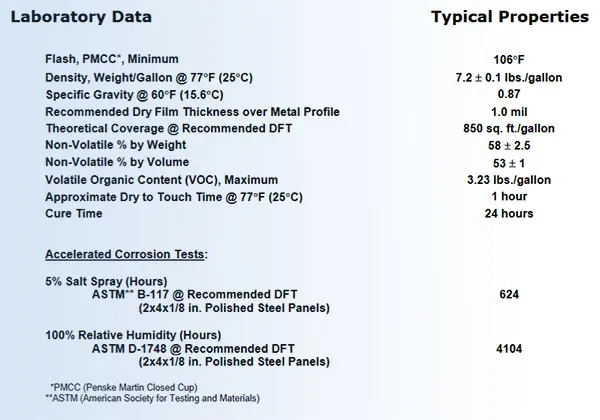

TECTYL 502C, Class I is a solvent cutback, corrosion preventive compound. The semi-firm film is amber and translucent. TECTYL 502C, Class I is approved under Military Specifications MIL-PRF16173E, Grade 2, for Class I, and MIL-P-116J, Type P-2. It is designed to protect ferrous and non-ferrous parts for indoor or covered storage and during shipment. The cured film of TECTYL 502C, Class I is compatible with a variety of oils and greases.

TECTYL 502C Surface Preparation:

The maximum performance of TECTYL 502C, Class I can be achieved only when the metal surfaces to be protected are clean, dry and free of rust, oil and mill scale. Daubert Chemical Company recommends that the metal substrate temperature be 50-95°F (10-35°C) at the time of product application

TECTYL 502C Application:

TECTYL502C, Class I isformulated to be used as supplied. Ensure uniform consistency prior to use. Continued stirring is generally not required. If the product thickens due to cold storage or loss of solvent during use, contact Daubert Chemical Company. DO NOT THIN TECTYL502C, Class I. Incorrect thinning will affect film build, dry time and product performance. Daubert Chemical Company recommends that the ambient and product temperature be 50 -95F (10 -35C) at time of application. TECTYL502C, Class I can be spray or dip applied

TECTYL 502C Removal:

TECTYL502C, Class I can be removed with TECTYLHPS solventborne thinner, vapor degreasing, hot alkaline wash, or low pressure steam. TECTYL502C, Class I can be removed from fabrics by normal dry cleaning procedures. Avoid the use of chlorinated or highly aromatic solvents when removing from painted surfaces, as these solvents may adversely affect paint.

TECTYL 502C Storage:

Store TECTYL502C, Class I at temperatures between 50-95°F (10-35°C). Mild agitation is recommended prior to use.

TECTYL 502C Caution:

Adequate ventilation is required for cure and to ensure against formation of combustible liquid.

THE PARTIALLY CURED FILM SHOULD NOT BE EXPOSED TO IGNITION SOURCES SUCH AS FLARES, FLAMES, SPARKS, EXCESSIVE HEAT OR TORCHES.

Refer to Valvoline’s Material Safety Data Sheet for additional handling and first aid information.

TECTYL 502C Note:

The addition of any product over or under this coating is not recommended. The use of additional coatings could result in chemical incompatibility, thus affecting the performance of this coating as stated in the Typical Properties section. If a primer, other than a Valvoline recommended product is required, written authorization must be obtained from Valvoline.