This hydraulic fluid is blended with highly refined mineral

based oils and modern additive technology to provide

protection against rust, wear, demulsibility, and to afford

greatly improved viscosity - temperature characteristics as

well as enhanced oxidation – corrosion resistance.

This hydraulic fluid is blended with highly refined mineral

based oils and modern additive technology to provide

protection against rust, wear, demulsibility, and to afford

greatly improved viscosity - temperature characteristics as

well as enhanced oxidation – corrosion resistance.

MIL-PRF-46170 SCOPE

This specification covers the

requirements for one type of synthetic

hydrocarbon base

hydraulic fluid.

The type of hydraulic fluid is as follows:

Type I - Undyed and Identified by Military Symbol FRH and NATO

Code No. H-544.MIL-PRF-46170 Intended useThe hydraulic fluid covered by this specification is intended for use in recoil

mechanisms and hydraulic systems of military ground vehicles

and equipment.

If used in other mechanisms or systems, a

study should be made to determine its applicability for such

usage, with particular attention given to operation at high

and low temperatures and the topic of elastomer compatibility.

The hydraulic fluid is rust inhibited and may be used as a

preservative medium for hydraulic systems and components.

The hydraulic fluid has a wide range of operating temperatures

and is thermally stable, corrosion inhibited, and fire

resistant. The combination of all of these quantities is not

found in commercial hydraulic fluids. This fluid is adopted

for military use by NATO countries. (NOTE: TYPE II of the

previous revision “C©?

is no longer available.)

MIL-PRF-46170

Fluid handling

Owing to the difficulty of preventing contamination after the

opening of a container, it is recommended that the hydraulic

fluid be purchased in 1-quart and 1-gallon containers by all

users. If the fluid is dispensed from larger containers,

strict procedures must be employed to exclude and remove

moisture, solid particles or other contaminants from the

fluid.

MIL-PRF-46170

Recommended corrosion inhibitor

It has been found that 1.75 ± 0.25% barium dinony1naphthalene

sulfonate provides the required degree of rust protection. The

diluent of the rust inhibitor should be the synthetic

hydrocarbon base stock.

MIL-PRF-46170

Handling and safety precautions

CAUTION: Personnel handling the product shall wear appropriate

impervious clothing to prevent repeated or prolonged skin

contact.

The local environmental officials will relate

health and safety implications as well as to prescribe precise

application of protective clothing. If skin or clothing

becomes moistened with the product, personnel should promptly

wash with soap or mild detergent and water. Respirators are

not required unless there is a potential for inhalation

exposure to misting. Personnel should wear protective clothing

when using the product and when cleaning up spills.

MIL-PRF-46170

Background (safety)

The product may contain 0.5% tricresyl phosphate, of which not

more than 0.01% may be present as the ortho isomer. If this

ortho isomer of tricresyl phosphate is absorbed through the

skin or taken internally, it may cause paralysis. The

corrosion

inhibitor contains barium. The accumulated waste

liquids will have the exterior of the outer pack marked as

containing barium and tricresyl phosphate to assist disposal

facilities to manage the product according to regulations

promulgated by the US Environmental Protection Agency under

Public Law 94-580, Resource Conservation and Recovery Act of

1976.

MIL-PRF-46170

Storage conditions

Prior to use of product in the intended equipment, the product

may be stored under conditions of covered or uncovered storage

on geographic areas ranging in temperature from –57°C to 71°C

(-71°F to 160°F).

MIL-PRF-46170

Interchangeability and compatibility

MIL-PRF-46170 fluids are not interchangeable with any other

fluids.

MIL-PRF-46170 fluids are not to be regarded as

compatible with any other fluids except those conforming to

MIL-PRF-5606, MIL-PRF-6083, MIL-PRF-83282, and MIL-PRF-87257.

Dilution with MIL-PRF-5606 or MIL-PRF-6083 severely lowers the

flash point.

MIL-PRF-46170 Qualification

The hydraulic fluid furnished under this specification shall

be

products that are authorized by the qualifying activity

for listing on the applicable qualified products list before

contract award. Any change in the formulation of a qualified

product will require re-qualification.

MIL-PRF-46170

Hydraulic fluid

The hydraulic fluid shall consist of a synthetic hydrocarbon

base

stock (alpha-olefin polymer). Additives shall not

include resins, gums, fatty oils, oxidized hydrocarbons,

chlorine or silica.

MIL-PRF-46170

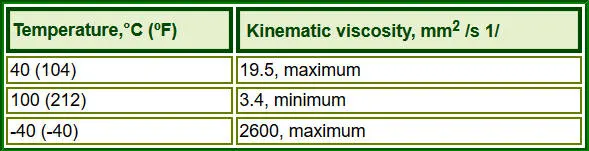

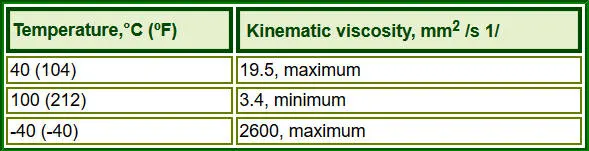

Kinematic viscosity

The kinematic viscosity of the hydraulic fluid shall be as

specified in table below, TABLE 1:TABLE I. Kinematic viscosity

1/ mm 2/s =

Square millimeters per second.

MIL-PRF-46170 Trace sediment

The hydraulic fluid shall have maximum trace sediment of 0.005

milliliter (mL)

MIL-PRF-46170 Water content

The

hydraulic fluid shall have maximum water weight of 0.05

percent.

MIL-PRF-46170 Acid or base number

The hydraulic fluid shall have maximum acid or base number of

0.20 milligrams (mg) of potassium hydroxide per gram of

hydraulic fluid (mg KOH/gram (g).

MIL-PRF-46170 Bulk modulus

The

isothermal secant bulk modulus of the hydraulic fluid shall be

1.379 x 106

kilopascals (kPa) minimum, at 40°C (104°F) at

pressures between 0 and 68 950 kPa.

MIL-PRF-46170 Water sensitivity

The light transmittance of a water-treated sample of hydraulic

fluid shall be a minimum of 90%.

MIL-PRF-46170 Corrosion protection (humidity cabinet)

The hydraulic fluid shall protect specially prepared steel

test panels to the extent that no more than three corrosion

dots, none of which exceed 1 mm in diameter, occur on any of

the panels.

MIL-PRF-46170 Corrosiveness (bimetallic couple)

The hydraulic fluid shall not promote galvanic

corrosion,

in excess of three spots, on any one of the steel test disks

covered with a brass clip.

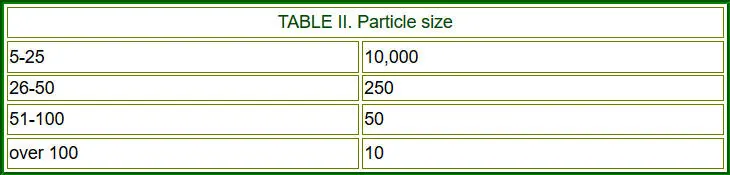

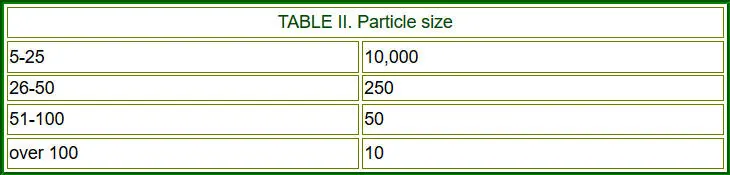

MIL-PRF-46170 Solid particle contamination

MIL-PRF-46170 Particle size

The

number of solid contamination particles per 100 mL of the

hydraulic fluid shall not be greater than the numbers

specified in table II.

MIL-PRF-46170 Gravimetric method

The solid particle contamination of the hydraulic fluid shall

not be greater than 0.5 mg/100 mL.

MIL-PRF-46170 Foaming characteristics

MIL-PRF-46170 Foaming tendency

The foam volume of the hydraulic fluid shall not exceed 65 mL

(following any of the 5-minute blowing periods of the foaming

characteristics test.

MIL-PRF-46170 Foam stability

There shall be no foam remaining in the hydraulic fluid, in

excess of a ring of bubbles around the edge of the test

container, following any of the 10-minute settling periods of

the foaming characteristics test.

MIL-PRF-46170 Wear (Lubricity)

During the wear test, the hydraulic fluid shall lubricate the

steel balls such that the average scar diameters on the steel

balls shall not exceed 0.30 mm if the test load is 147 Newtons

(N), or 0.65 mm if the test load is 392 N.

MIL-PRF-46170 High temperature - high pressure

spray ignition

The hydraulic

fluid, when sprayed and ignited, shall be self-extinguishing.

MIL-PRF-46170 Linear flame propagation

The linear flame propagation rate of the hydraulic fluid shall

not exceed 0.30 centimeters per second (cm/s).

MIL-PRF-46170 Relative Density (specific gravity)

The relative density of transparent low-viscosity hydraulic

fluid samples submitted for conformance testing shall be

reproducible to no more than +/-0.0012 and repeatable to no

more than +/-0.0005 (no units) between the temperature range

of -2°C to +24.5°C (29°F to 76°F), and no more than +/-0.008

from the relative density of the sample approved in

qualification testing. Relative density shall be expressed at

60°F/60°F or at some temperature between 29°F to 76°F.

Temperatures may be the same or different, but in both cases

shall be explicitly stated, for example, 65°F/65°F, or

50°F/65°F. Report the final value as relative density, with no

dimensions, at the two reference temperatures, to the nearest

0.0001.

MIL-PRF-46170 Interface requirements

Corrosiveness and oxidation stability (metal protection)

MIL-PRF-46170 Weight change of test specimens

The hydraulic fluid shall not produce corrosion or oxidation

effects such that the weight change of the metal specimens,

except for copper specimen, exceeds a gain or loss of 0.2

milligrams per square centimeter (mg/cm2). For the copper

specimen, the weight gain or loss shall not exceed 0.6 mg/cm2

MIL-PRF-46170 Appearance of test specimens

The hydraulic fluid shall not cause etching, pitting, or

visible corrosion on the surface of the metal specimens,

except for the copper specimen. Any corrosion produced on the

surface of the copper specimen shall not be greater than No. 2

of ASTM D130 Copper Corrosion Standards.

Viscosity change

The viscosity of the oxidized hydraulic fluid at 40°C (104°F)

shall not change more than ±10% from the initial viscosity

measured at 40°C (104°F).

Acid or base number change

The

acid or base number of the oxidized hydraulic fluid shall not

increase more than 0.30 mg KOH/g over the initial acid or base

number.

MIL-PRF-46170 Insoluble material

The oxidized hydraulic fluid shall exhibit no insoluble

materials or gum when examined.

MIL-PRF-46170 Swelling of synthetic rubber

Following immersion in the hydraulic fluid at a temperature of

70°C (158°F) for 168 hours, standard synthetic rubber NBR-L,

in accordance with (IAW) SAE AMS 3217/2B, shall exhibit a

percent volume change within the range of 15 to

25%.

MIL-PRF-46170 Compatibility

The hydraulic fluid shall be compatible, in all

concentrations, with each of the fluids approved under this

specification, as well as hydraulic fluids conforming to:

MIL-PRF-5606, MIL-PRF-6083, MIL-PRF-83282, and MIL-PRF-87257

MIL-PRF-46170 Fire point

The minimum fire point of the hydraulic fluid shall be 246°C

(475°F)

.

MIL-PRF-46170 Pour point

The maximum pour point of the hydraulic fluid shall be -54°C

(-65°F)

MIL-PRF-46170 Evaporation loss

The maximum mass percent evaporation loss of the hydraulic

fluid shall be 5%.

MIL-PRF-46170 Autoignition temperature

The minimum autoignition temperature of the hydraulic

fluid

shall be 343°C (649°F).

MIL-PRF-46170 Low temperature stability

The hydraulic fluid shall show no evidence of gelling,

crystallization, solidification or separation of insoluble

material when subjected to a temperature of -40 ± 6°C (-40

±11°F) for 72 hours.

MIL-PRF-46170 Packaging

For acquisition purposes, the packaging requirements shall be

specified in the contract or order. When actual packaging of

materiel is to be performed by DoD or in-house contractor

personnel, these personnel need to contact the responsible

packaging activity to ascertain packaging requirements.

Packaging requirements are maintained by the Inventory Control

Point's packaging activities within the Military Services or

Defense Agency, or within the military service's system

commands. Packaging data retrieval is available from the

managing Military Department's or Defense Agency's automated

packaging files, CD-ROM products, or by contacting the

responsible packaging activity.

| MIL-PRF-46170

SPECIFICATION, GRADE, TYPE, CLASS |

MIL-PRF-46170

DESCRIPTION |

MIL-PRF-46170

USES |

|---|

MIL-PRF-46170 covers the requirements for one type of synthetic hydrocarbon base hydraulic fluid

Status: ACTIVE

| MIL-PRF-46170 Hydraulic Fluid, Rust Inhibited, Fire Resistant, Synthetic Hydrocarbon Base | Intended for use in recoil mechanisms and hydraulic systems of military ground vehicles and equipment. If used in other mechanisms or systems, a study should be made to determine its applicability for such usage

|

|---|

MIL-SPEC, military

specification, military standard (MIL-STD) is a United States Defense

standard used to describe a product that meets specific performance and

manufacturing standards for equipment and chemicals.

Other non-defense government

organizations, technical organizations and industry may also use

military specifications are not just limited to The Department of

Defense, as other government organizations and Industry use them as

well.

Here is a Q&A from the Department of

Defense:

What is a performance spec?

A.

A performance specification states requirements in terms of the

required results with criteria for verifying compliance, but

without stating the methods for achieving the required results.

A performance specification defines the functional requirements

for the item, the environment in which it must operate, and

interface and interchangeability characteristics.

Q. What guidance have we given on how to write a performance

specification?

A. Writing performance specifications is not a new concept. We have

been teaching how to write performance requirements for years at

our specification training course. It has received extra

emphasis in our training on how to write Commercial Item

Descriptions. What is new is that we are now designating

documents as "performance specifications."

Q. If you have a performance spec that is MILSPEC, is a waiver needed?

A. No.

Q. Is it possible for a general specification to be designated as

performance and its associated specification sheets to be

designated as detail?

A. No. Since a general specification must be used together with a

specification sheet, the fact that the specification sheet is

detail requires the general specification also to be designated

as detail.

Q. Within the same family of specification sheets, is it possible for some

to be designated as detail and others to be performance?

A. Generally, no. The decision whether to convert a family of

specification sheets to performance specifications must be

consistent across-the-board. In some cases, however, the number

of specification sheets that must be converted to performance

specifications may be very large, making it difficult to convert

all of them at one time. In this situation, there may be a

temporary blend of detail and performance specification sheets

within the same document number series. This situation is

acceptable as long as the goal is to convert all of them to

performance specifications.

Q. Can a performance spec ever cite a detail spec as a requirement?

A. The citing of a detail spec as a requirement does not

automatically mean that a spec is not performance, but it is a

strong indicator that as spec may not be performance.

Performance specs should not cite any detail spec as a

requirement if it demands a specific design solution. But

performance specs may cite a detail spec if it relates to a

physical or operational interface requirement.

For example, it would be permissible to have a requirement in a performance engine

specification that required the engine to operate with specific

substances, such as lubricating oil or fuel, which conform to

detail specs. The requirement that the engine be able to operate

on a specific type of fuel is an operational interface

requirement and does not dictate the specific design of the

engine. However, it would not be permissible in a performance

spec to require the engine be made of certain materials or that

the various engine components conform to detail specs since such

requirements would dictate specific design solutions instead of

stating the performance expected.

Q. I'm writing a spec that describes a "kit."

Should

it be a detail (MIL-DTL-) or a performance (MIL-PRF-)

specification?

A. In general, the answer is that it will likely be a detail

specification; however, there can be exceptions. A spec for a

kit describes a collection of related items, such as adapters,

couplings, bags, tools, attachments, or accessories. A kit may

contain items for installing, testing, or starting up a system

or piece of equipment; it may be provided to equip an existing

system for specific functions; or it may be used to adapt

equipment to meet new or specialized conditions. If the spec

writer were careful to write all of the requirements for the

kit's contents in terms of form, fit, function, and interfaces,

and to cite only performance-type documents, the resulting spec

would support a MIL-PRF designation. As is frequently the case,

however, if one or more of the kit's components are described

using a specific design solution, Technical Data Package, MIL-DTL

type spec, or a non-government standard that contains detail

design requirements, the kit spec must be designated as a MIL-DTL.

The spec writer needs to keep in mind that all of the

requirements for all of the kits' components must be stated in

performance terms in order to produce a MIL-PRF.

Welcome! Thanks for visiting.

Welcome! Thanks for visiting.

Welcome! Thanks for visiting.

Welcome! Thanks for visiting.

Welcome! Thanks for visiting.

Welcome! Thanks for visiting.