AEROSHELL Grease 64

Replaces AEROSHELL Grease 33MS and AEROSHELL Grease 17

AEROSHELL Grease 64 is available in 14 oz grease gun cartridges & 37.5 pound pails.

AEROSHELL Grease 64 shares the same advanced grease technology AeroShell Grease 33, AeroShell Grease 64 also possesses the extreme pressure (EP) characteristics provided by molybdenum disulphide.

AEROSHELL Grease 64 contains a synthetic oil and must not be used with incompatible seal materials. AeroShell Grease 64 comprises AeroShell Grease 33 fortified with 5% molybdenum disulphide. It possesses the enhanced anti-wear and anti-corrosion properties of AeroShell Grease 33 with the added EP (Extreme Pressure) properties provided by the addition of a solid lubricant. The useful operating temperature range is –73°C to +121°C.

AEROSHELL Grease 33 and 64 APPLICATIONS

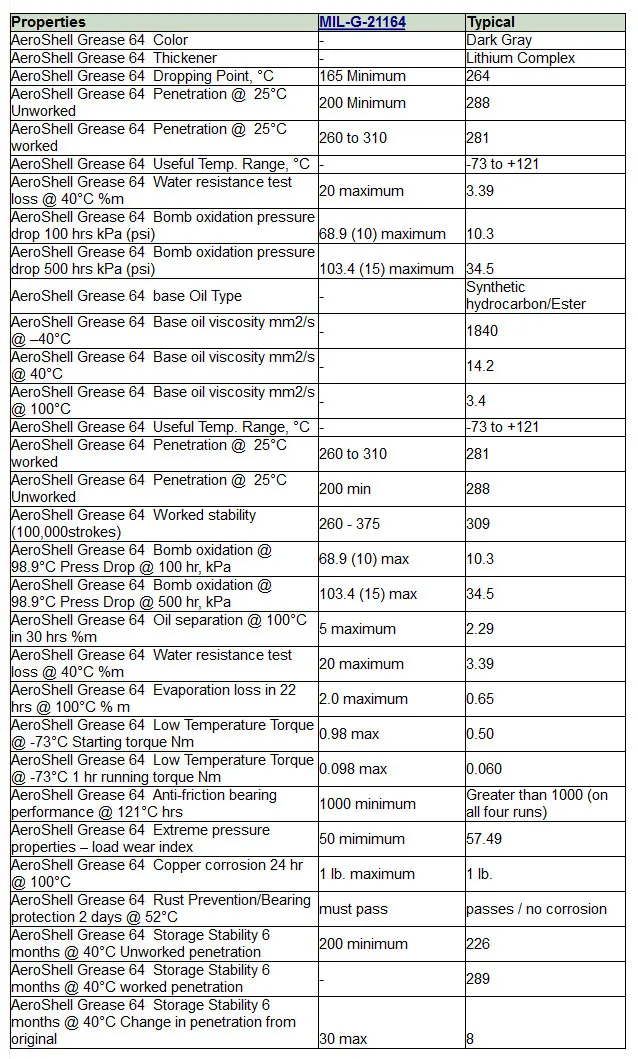

Meets MIL-SPEC: MIL-G-21164 AeroShell Grease 33 has established itself as the answer to most of the airframe’s General Purpose, airframe greasing requirements, being approved for use in Boeing, Airbus and many other aircraft types.

AeroShell Grease 33 sets the standard with exceptional anti-corrosion and anti-wear performance while allowing aircraft operators to shrink their grease inventory and reduce the risk of misapplication. However, there remains a small number of highly loaded, sliding applications on the airframe where the additional boost of molybdenum disulphide will always be required. To address this need, Shell Aviation has developed AeroShell Grease 64 .

Sharing the same advanced grease technology as its parent, AeroShell Grease 64 also possesses the extreme pressure (EP) characteristics provided by molybdenum disulphide. AeroShell Grease 64 contains a synthetic oil and must not be used with incompatible seal materials.

Shell says of their products, "Whatever your industry and however specialized your equipment, Shell’s products and services are designed to add value to your operation. Discover how using the right lubricant can bring you substantial savings by helping to maximize equipment efficiency, prolong component life and reduce downtime.